Permanent Vinyl Shiny Side Up Or Down - A Crafting Guide

When you are working with craft vinyl, a common question pops up about which side of your permanent vinyl should face upwards. It seems like a simple thing, yet getting it right makes a real difference in how your projects turn out. The way you place your vinyl sheet can affect how well it sticks and how it looks once it is on something. You want your creations to last, you know, for a good long while, and understanding this little detail helps make sure they do.

This kind of vinyl, the permanent sort, is made to stay put for a very long time. It's not like something that just peels off easily after a short while. Think of it as something that is constant and lasting, rather than just for a short period. So, when you are putting it on a cup or a sign, you really want it to stick well and not come off. Knowing which side is which is a big part of making sure that happens, as a matter of fact.

Getting your vinyl on the right way means your finished piece will look better and hold up over time. It is all about making sure the sticky part does its job correctly and that the color or pattern you want to see is visible. We are going to look at what makes this kind of vinyl stick, how to tell the sides apart, and what happens if you get it mixed up, which can be a little frustrating, to be honest.

- Boynextdoor Photocard Template

- Jayde Cyrus Tits

- Laura Haddock Angelina Jolie

- Jailyne Ojeda Adin Ross

- Is Gmovies Down

Table of Contents

- What Makes Permanent Vinyl Stay Put?

- How Can You Tell the Permanent Vinyl Shiny Side from the Dull Side?

- Why Does Permanent Vinyl Shiny Side Up Matter?

- Common Mix-Ups with Permanent Vinyl Placement

- Tips for Working with Permanent Vinyl Sheets

- Making Your Permanent Vinyl Projects Last

- Troubleshooting Permanent Vinyl Sticky Situations

What Makes Permanent Vinyl Stay Put?

The very idea of something being "permanent" means it is meant to continue or endure without a big change. When we talk about permanent vinyl, we mean it is designed to last for a long time, or even for what feels like forever, once it is put down. This is very different from temporary vinyl, which you can pull off easily. The lasting quality comes from a strong adhesive, a kind of sticky glue, that is on one side of the vinyl material. This adhesive forms a very strong bond with the surface you are putting it on. It is not expected to change its status or condition once it is applied, which is kind of the whole point, you know.

This sticky stuff is usually covered by a paper backing, often called a liner. This liner protects the adhesive until you are ready to use the vinyl. The vinyl itself is a thin, flexible material, often made of PVC, that holds the color or pattern you want to use. So, you have the vinyl material on top, then the adhesive layer, and then the paper liner at the very bottom. When you are getting ready to cut your design, you want to make sure the machine cuts through the vinyl layer but leaves the paper liner untouched. That way, the design stays in one piece on its backing until you are ready to transfer it, which is actually pretty clever.

The strength of the bond that permanent vinyl creates means it is not just for things you might want to remove later. It is for items that you want to keep decorated for a very long time, like outdoor signs, car decals, or mugs that will go through the wash many times. This lasting quality is what sets it apart. It is constant and lasting, as opposed to temporary, which is a good thing to remember when picking your materials, at the end of the day.

How Can You Tell the Permanent Vinyl Shiny Side from the Dull Side?

It can be a little tricky sometimes to figure out which side is which, especially if you are new to working with vinyl. Most permanent vinyl has a face side, which is the part with the color or pattern that you want to see, and a backing side, which is the paper liner protecting the sticky part. The face side is typically the shiny side, or at least it has a smoother, more finished look. The backing, on the other hand, is usually duller, more like plain paper, and sometimes has a grid pattern printed on it, which is pretty helpful for cutting straight lines, incidentally.

When you hold a piece of permanent vinyl, you will often notice that one side has a bit of a gloss or a sheen to it. This is usually the side that will show your design. The other side, the paper backing, will feel different to the touch; it is often a bit rougher or just feels like paper. If you are ever in doubt, you can try to gently peel a tiny corner. The side that starts to separate from the paper is the vinyl itself, and the part that is sticking to the paper is the adhesive. You want to cut on the side that has the color or design, not the paper side, basically.

Some vinyl sheets might have a matte finish on the front, which means it won't be shiny at all. In those cases, feeling the difference between the vinyl and the paper backing becomes even more important. The paper backing will almost always feel like paper, while the vinyl, even if it is matte, will have a different texture, more like a thin plastic film. It is a good idea to get a feel for your materials before you start cutting, just to be sure, you know.

The Right Way for Permanent Vinyl

When you are getting ready to put your permanent vinyl into a cutting machine, the rule of thumb is to place it with the shiny, or colored, side facing up. This is the side your machine's blade is meant to cut. The machine will cut your design into this top layer of vinyl, leaving the paper backing untouched. This means that after the cut, your design will still be attached to the paper backing, ready for you to "weed" away the extra bits and then transfer it. It is how you ensure the design comes out correctly and is ready to be put onto your chosen item, which is pretty important, really.

The cutting machine's software usually assumes you are placing the vinyl this way. It mirrors the design so that when it cuts from the top, the final image will be oriented correctly when you flip it over to stick it down. If you put the vinyl in upside down, the design will be cut in reverse, and it might not fit where you want it to go, which can be quite a bother, as a matter of fact. So, shiny side up, always, for cutting.

This method also protects the adhesive layer. By cutting from the top, the blade only goes through the vinyl material. The sticky part stays clean and ready to bond with your project surface. This is key for the vinyl to truly be permanent, meaning it lasts for a long, indefinite period, without regard to unforeseeable conditions, as the definition of permanent suggests. You want that strong, lasting connection, you know.

What Happens If You Get the Permanent Vinyl Wrong?

If you accidentally put your permanent vinyl into the machine with the paper backing facing up, a few things can go wrong. First, your machine will try to cut through the paper backing, which is not what it is designed to do. This can dull your blade quickly, making future cuts less clean and requiring you to replace the blade sooner than you would like. It is a bit like trying to cut cardboard with a dull knife; it just does not work as well, you see.

Second, and perhaps more frustratingly, the design will be cut in reverse. When you peel it off the backing, it will be mirrored. For most designs, especially those with text or specific shapes, this means the design will be unusable. Imagine trying to put a mirrored word on a sign; it would look backwards, which is pretty much useless. This can waste your material and your time, which is something you definitely want to avoid, basically.

Also, if the blade cuts through the paper backing, it might not cut cleanly through the vinyl itself. This can make weeding, the process of removing the extra vinyl around your design, much harder. You might find parts of your design tearing or sticking where they should not, making the whole process more difficult than it needs to be. So, paying attention to which side is up really saves you a lot of trouble and makes sure your project turns out right, you know.

Common Mix-Ups with Permanent Vinyl Placement

It is pretty common for people, especially when they are just starting out, to mix up the sides of their permanent vinyl. One of the main reasons for this is that some vinyls look very similar on both sides, or perhaps the "shiny" side is not very shiny at all, maybe it is a matte finish. This can lead to confusion about which way to load the material into the cutting machine. It is a little frustrating when that happens, too it's almost.

Another common mistake happens when people are used to working with heat transfer vinyl (HTV). With HTV, you often place the shiny side (which is the carrier sheet) down on the mat, and you cut from the duller, adhesive side. This is the opposite of how you work with adhesive vinyl, like permanent vinyl. So, if you switch between different types of vinyl often, it is easy to get them mixed up. It is a good idea to double-check which type of vinyl you are using before you start cutting, just to be on the safe side, you know.

Sometimes, the lighting in your workspace can make it hard to see the difference between the shiny and dull sides. Poor lighting can obscure the subtle sheen of the vinyl, making both sides appear similar. It is always a good idea to work in a well-lit area where you can clearly see the texture and finish of your materials. This small step can prevent big headaches later on, honestly.

Tips for Working with Permanent Vinyl Sheets

To make sure you always get your permanent vinyl placed correctly, here are a few simple tips. First, always do a quick check of both sides of your vinyl sheet. Feel the texture and look for any sheen. The side that feels smoother or looks more finished is usually the face side. The paper backing will feel like, well, paper, and often has a grid on it. This simple check can save you a lot of trouble, you know.

Second, if you are still unsure, try a very small test cut. Cut a tiny shape, like a small circle, in a corner of your vinyl. If the cut goes through the colored vinyl and leaves the backing intact, you have loaded it correctly. If it cuts through the paper backing, you know you need to flip it over. This little test can prevent wasting a whole sheet of material, which is pretty useful, really.

Third, always make sure your cutting mat is clean and sticky enough. A good, sticky mat holds the vinyl firmly in place, preventing it from shifting during the cut. If the vinyl moves, your design can get messed up, regardless of whether you loaded it correctly. A clean mat helps ensure a good bond, which is pretty important for a clean cut, you know.

Making Your Permanent Vinyl Projects Last

The whole point of using permanent vinyl is for your creations to last a very long time. This type of vinyl is intended to exist or function for a long, indefinite period, without regard to unforeseeable conditions. To help it live up to its name, there are a few things you can do. First, make sure the surface you are putting the vinyl on is clean and dry. Any dust, grease, or moisture can prevent the adhesive from sticking properly, making your "permanent" project less so, which is not what you want, obviously.

Once you have applied the vinyl, give it some time to cure, or set. The adhesive needs time to form its strongest bond with the surface. This can take anywhere from 24 to 72 hours, depending on the vinyl and the surface. During this time, try not to wash or put too much stress on the item. This waiting period helps ensure the vinyl truly becomes constant and lasting, rather than temporary, as the definition suggests, you see.

For items that will be washed, like mugs or tumblers, hand washing is usually best. Even though permanent vinyl is tough, harsh dishwashers can sometimes be too aggressive and shorten its lifespan. Hand washing gently helps preserve your design for much longer. It is all about giving your finished project the best chance to endure, which is pretty much the goal, in a way.

Troubleshooting Permanent Vinyl Sticky Situations

Even with all the right steps, you might run into a few sticky situations with permanent vinyl. If your vinyl is not sticking well, first check the surface. Is it clean? Is it smooth? Permanent vinyl likes smooth, non-porous surfaces best. If the surface is textured or rough, the vinyl might not get enough contact to form a strong bond, which is a common issue, you know.

Another issue might be that you are not applying enough pressure when putting the vinyl down. After you place the vinyl, use a squeegee or a credit card to rub firmly over the design. This helps push out any air bubbles and ensures the adhesive makes good contact with the surface. You want to rub pretty hard, really, to get it to stick well.

If your vinyl is peeling up at the edges, it might be due to a few things. It could be that the surface was not clean enough, or maybe the vinyl did not get enough cure time. Sometimes, if the design has very thin lines or small details, those bits might be more prone to lifting. For those tiny pieces, a little extra pressure during application and a longer cure time can help. It is all about making sure that lasting bond is formed, you know, so your project stays looking good for a long, indefinite period, as intended.

This article covered how permanent vinyl is designed to last a very long time, much like something that continues without marked change. We looked at how to tell the shiny, usable side from the dull paper backing, and why putting the shiny side up when cutting is important for a good outcome. We also discussed what can happen if you get the placement wrong, common mix-ups, and simple tips for working with permanent vinyl sheets. Finally, we went over ways to make your permanent vinyl projects endure and how to handle situations where the vinyl might not stick as expected, all to help your creations remain constant and lasting.

- Obsessed With Zoe Nude

- Saddam Hussein Tiger

- Serena Sanchez Chino

- Https Onlyfans Com Omgjasmin

- Christian Mccaffrey Racist

:max_bytes(150000):strip_icc()/demi-vs-permanent-hair-color-GettyImages-1312483428-70024c3cdb174a9097375155d4fc8a83.jpg)

Semi-Permanent vs. Demi-Permanent Hair Color

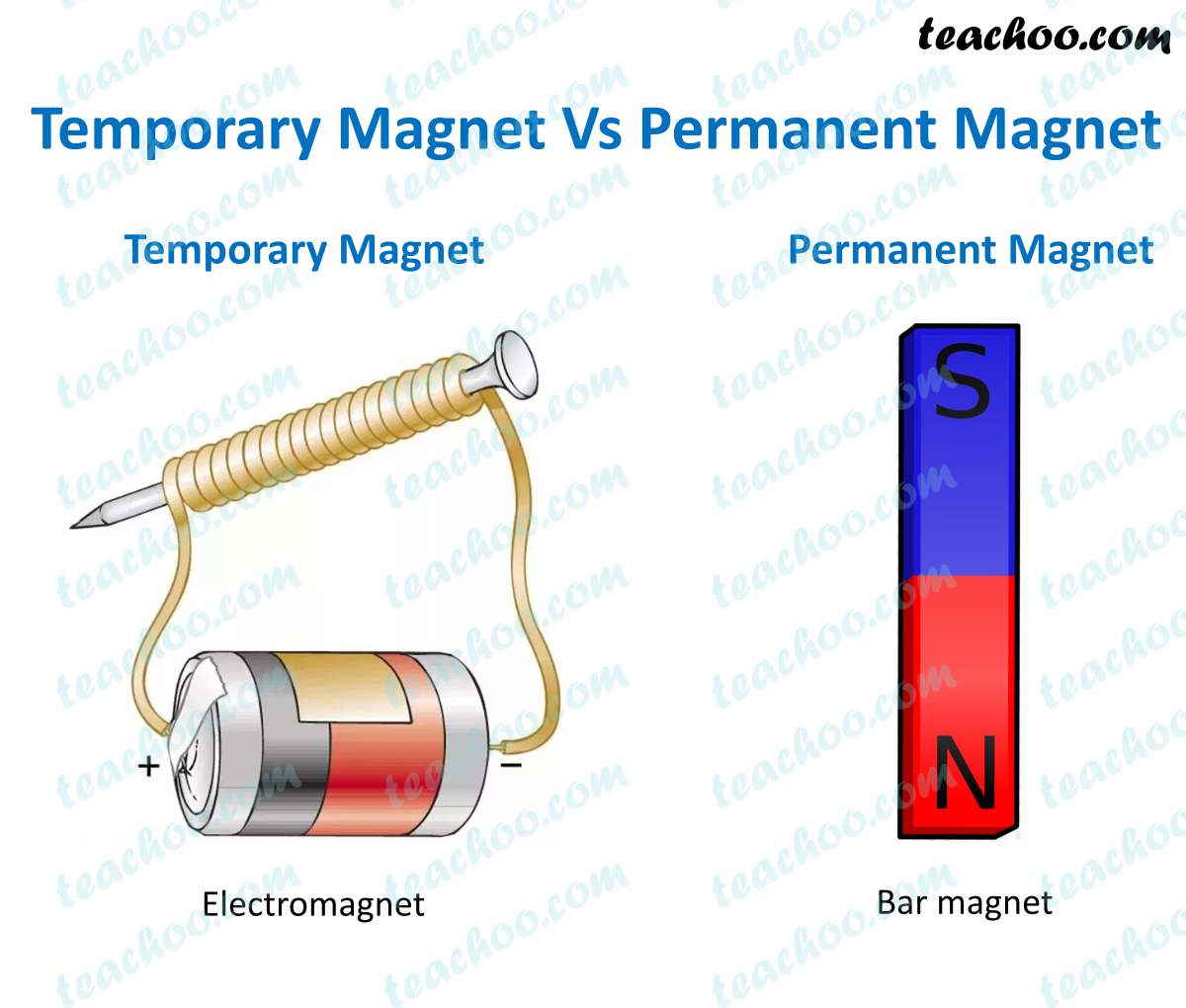

Difference between Temporary and Permanent Magnet - Teachoo

Permanent Bracelets | Mountz Jewelers | Carlisle, Camp Hill, Colonial